Home

>> Products

>> MITSUBISHI

>> Ans/QnAs series PLC

>> Computer communication module

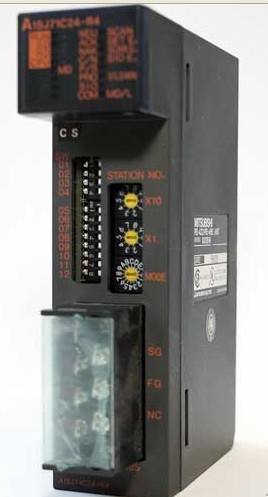

>> A1SJ71C24-R4 | MITSUBISHI Computer link module A1SJ71C24-R4

A1SJ71C24-R4 | MITSUBISHI Computer link module A1SJ71C24-R4

MITSUBISHI A1SJ71C24-R4 Manual And Instructions

A1SJ71C24-R4 datasheetPDF datasheet

A1SJ71C24-R4 User's Manual

MITSUBISHI A1SJ71C24-R4 Product information and technical parameters:

Brand: MITSUBISHI

Name: Computer link module

Model: A1SJ71C24-R4

...More relevant models >>>>

A1SJ71C24-R4 datasheetPDF datasheet

A1SJ71C24-R4 User's Manual

MITSUBISHI A1SJ71C24-R4 Product information and technical parameters:

Brand: MITSUBISHI

Name: Computer link module

Model: A1SJ71C24-R4

3C-2V/5C-2V coaxial cable between the single bus PC network (control station / common station) / remote I/O network (remote master).

The response time of PLC is the interval between the time of the change of the external output signal of the PLC and the time of the change of the external output signal which is controlled by it,

Lag time, this is the time constant of the input circuit,

The time constant of the output circuit, the arrangement of the user statement and the use of the instruction,

The cycle scan mode of PLC and the way of PLC to refresh the I/O and so on MITSUBISHI A1SJ71C24-R4 A1SJ71C24-R4

This phenomenon is called the I/O delay time effect.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order MITSUBISHI A1SJ71C24-R4.

So, sometimes also known as the order control.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. Input points: 32 points MITSUBISHI A1SJ71C24-R4.

Input voltage and current: 7mA DC24V.

Input response time: 10ms.

16 point /1 a public side.

Positive pole sharing.

Output points: 24 points.

Output voltage: DC24V.

OFF leakage current: 0.1mA.

Output response time: 12ms.

Output type: transistor output.

8 point /1 a public side.

With the surge absorber.

34 point terminal station.

PLC is introduced by the relay control technology after the development of micro processing technology,

Can be easily and reliably used for switching control.

As the analog quantity can be converted into digital quantity, the number of digital quantity is just a number of switching value,

Therefore, after the conversion of analog, PLC can also be reliable for processing control.

Because the continuous production process often has the analog quantity, the analog quantity control is sometimes called process control.

Analog quantity is not electricity, and PLC can only handle digital quantity, quantity of electricity.

All to realize the conversion between them to have the sensor, the analog quantity into a number of power.

If this power is not standard, but also through the transmitter,

The non-standard power into a standard electrical signal, such as 1-5V, 4-20mA, 0-10V, etc..

At the same time, there is also an analog input unit (A/D),

Transform these standard elecctrical signals into digital signals,

The analog output unit (D/A), in order to transform the digital quantity after PLC processing into analog quantity -- standard electric signal A1SJ71C24-R4.

So the standard telecommunication number, the conversiion between the number of operations to use a variety of computing A1SJ71C24-R4.

This requires the resolution of the analog unit and the standard electrical signal.

The response time of PLC is the interval between the time of the change of the external output signal of the PLC and the time of the change of the external output signal which is controlled by it,

Lag time, this is the time constant of the input circuit,

The time constant of the output circuit, the arrangement of the user statement and the use of the instruction,

The cycle scan mode of PLC and the way of PLC to refresh the I/O and so on MITSUBISHI A1SJ71C24-R4 A1SJ71C24-R4

This phenomenon is called the I/O delay time effect.

Switch volume control is designed to,

According to the current input combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order MITSUBISHI A1SJ71C24-R4.

So, sometimes also known as the order control.

And sequential control is divided into manual, semi-automatic or automatic.

And the control principle is decentralized, centralized and hybrid control three. Input points: 32 points MITSUBISHI A1SJ71C24-R4.

Input voltage and current: 7mA DC24V.

Input response time: 10ms.

16 point /1 a public side.

Positive pole sharing.

Output points: 24 points.

Output voltage: DC24V.

OFF leakage current: 0.1mA.

Output response time: 12ms.

Output type: transistor output.

8 point /1 a public side.

With the surge absorber.

34 point terminal station.

PLC is introduced by the relay control technology after the development of micro processing technology,

Can be easily and reliably used for switching control.

As the analog quantity can be converted into digital quantity, the number of digital quantity is just a number of switching value,

Therefore, after the conversion of analog, PLC can also be reliable for processing control.

Because the continuous production process often has the analog quantity, the analog quantity control is sometimes called process control.

Analog quantity is not electricity, and PLC can only handle digital quantity, quantity of electricity.

All to realize the conversion between them to have the sensor, the analog quantity into a number of power.

If this power is not standard, but also through the transmitter,

The non-standard power into a standard electrical signal, such as 1-5V, 4-20mA, 0-10V, etc..

At the same time, there is also an analog input unit (A/D),

Transform these standard elecctrical signals into digital signals,

The analog output unit (D/A), in order to transform the digital quantity after PLC processing into analog quantity -- standard electric signal A1SJ71C24-R4.

So the standard telecommunication number, the conversiion between the number of operations to use a variety of computing A1SJ71C24-R4.

This requires the resolution of the analog unit and the standard electrical signal.

...More relevant models >>>>

Last one: MITSUBISHI Computer link module A1SJ71C24-R2

Last one: MITSUBISHI Computer link module A1SJ71C24-R2 next one: MITSUBISHI MODBUS interface module A1SJ71UC24-R2-S2

next one: MITSUBISHI MODBUS interface module A1SJ71UC24-R2-S2

Related download