Home

>> Products

>> MITSUBISHI

>> Q series PLC

>> Base Board

>> motherboard

>> Q38RB | MITSUBISHI Main substrate of redundant system of power supply Q38RB

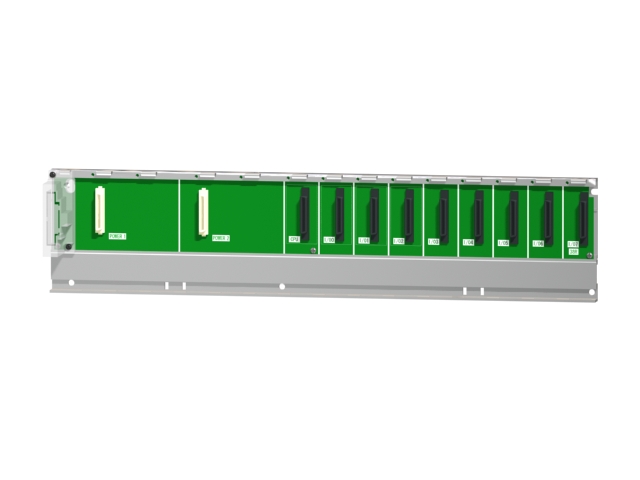

Q38RB | MITSUBISHI Main substrate of redundant system of power supply Q38RB

MITSUBISHI Q38RB Manual And Instructions

Q38RB datasheetPDF datasheet

Q38RB datasheetPDF datasheet

MITSUBISHI Q38RB Product information and technical parameters:

Brand: MITSUBISHI

Name: Main substrate of redundant system of power supply

Model: Q38RB

8 slots.

The main substrate needs to be equipped with CPU and power supply.

Double power supply mode power supply redundancy system.

Requires 1 power modules.

Used to install Q series modules.

Optimal network matching for application purposes and applications,

Seamless communication between different hierarchical systems.

Enhancing the ability of information communication through network.

This is also a major task in the field of automation.

Network environment provided by Q series

Is truly open & seamless.

Including based on universal ethernet,

Achieve easy management of the environment "IE Control CC-Link" controller network,

As well as in its management to achieve a high-speed, high-capacity transmission of the "IE Field CC-Link" field network.

Also including Japan''s first, to achieve the world standard,

And get the SEMI certification of the field network "CC-Link",

And inherited the design concept of the provincial distribution network CC-Link/LT".

And support sensor networks "AnyWire",

To enrich the lineup flexibility to integrate the various layers of automation network.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow and motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields.

Can also be used in combination with the CPU module to achieve appropriate control.

...More relevant models >>>>

Q38RB datasheetPDF datasheet

Q38RB datasheetPDF datasheet

MITSUBISHI Q38RB Product information and technical parameters:

Brand: MITSUBISHI

Name: Main substrate of redundant system of power supply

Model: Q38RB

8 slots.

The main substrate needs to be equipped with CPU and power supply.

Double power supply mode power supply redundancy system.

Requires 1 power modules.

Used to install Q series modules.

Optimal network matching for application purposes and applications,

Seamless communication between different hierarchical systems.

Enhancing the ability of information communication through network.

This is also a major task in the field of automation.

Network environment provided by Q series

Is truly open & seamless.

Including based on universal ethernet,

Achieve easy management of the environment "IE Control CC-Link" controller network,

As well as in its management to achieve a high-speed, high-capacity transmission of the "IE Field CC-Link" field network.

Also including Japan''s first, to achieve the world standard,

And get the SEMI certification of the field network "CC-Link",

And inherited the design concept of the provincial distribution network CC-Link/LT".

And support sensor networks "AnyWire",

To enrich the lineup flexibility to integrate the various layers of automation network.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow and motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields.

Can also be used in combination with the CPU module to achieve appropriate control.

Input / output points: 4096 points.

Number of input and output elements: 8192.

Program capacity: 40 K step.

Processing speed: 0.0095 s.

Program memory capacity: 160 KB.

Support USB and RS232.

Support installed memory card.

Providing high speed communication between multiple CPU.

High speed and high precision data processing MITSUBISHI Q38RB.

The processing speed of the real number (floating point) arithmetic has been greatly improved,

Addition instruction reached 0 Q38RB014 mu s,

Therefore, it can support the request of high-speed, high-precision processing data processing.

In addition, the new addition of double precision floating point arithmetic instructions,

Simplify the programming, reduces the computational error when executing complex formula MITSUBISHI Q38RB.

Shorten the fixed scan interrupt time, high precision device.

The minimum interval of the fixed period interrupt program is reduced to 100 s.

The high speed signal can be accurately obtained, which makes the contribution to the higher precision of the device.2 axis, differential drive output type.

2 axis linear interpolation.

2 axis interpolation.

Control unit: mm, inch, degree, pulse MITSUBISHI Q38RB.

Location data: 600 data / axis.

Maximum pulse output: 1Mpps.

40 pin connector.

Positioning module.

Open collector output.

Differential driver output.

Based on the use of open collector outputs and differential drive output type 2 types.

Differential driver output type positioning module can transmit high speed instruction pulse (up to 4Mpps) to the servo amplifier reliably,

Transmission distance of up to 10 meters, to achieve high speed and high precision control.

(the command pulse of the open collector positioning module is highest 200kpps.)

Can also meet the needs of high speed, high precision control.

Most suitable analog modules for high speed conversion control.

Can provide a variety of analog and digital analog conversion module products.

These modules have a variety of functions, in the connection of equipment, to achieve the greatest flexibility.

Can meet the inverter control, such as high-speed conversion needs.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow aand motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields Q38RB.

Can also be used in combination with the CPU module to achieve appropriate control.

The poossibility of expanding control with intelligent function Q38RB.

Providing a variety of analog modules, is the ideal choice for process control applications.

Number of input and output elements: 8192.

Program capacity: 40 K step.

Processing speed: 0.0095 s.

Program memory capacity: 160 KB.

Support USB and RS232.

Support installed memory card.

Providing high speed communication between multiple CPU.

High speed and high precision data processing MITSUBISHI Q38RB.

The processing speed of the real number (floating point) arithmetic has been greatly improved,

Addition instruction reached 0 Q38RB014 mu s,

Therefore, it can support the request of high-speed, high-precision processing data processing.

In addition, the new addition of double precision floating point arithmetic instructions,

Simplify the programming, reduces the computational error when executing complex formula MITSUBISHI Q38RB.

Shorten the fixed scan interrupt time, high precision device.

The minimum interval of the fixed period interrupt program is reduced to 100 s.

The high speed signal can be accurately obtained, which makes the contribution to the higher precision of the device.2 axis, differential drive output type.

2 axis linear interpolation.

2 axis interpolation.

Control unit: mm, inch, degree, pulse MITSUBISHI Q38RB.

Location data: 600 data / axis.

Maximum pulse output: 1Mpps.

40 pin connector.

Positioning module.

Open collector output.

Differential driver output.

Based on the use of open collector outputs and differential drive output type 2 types.

Differential driver output type positioning module can transmit high speed instruction pulse (up to 4Mpps) to the servo amplifier reliably,

Transmission distance of up to 10 meters, to achieve high speed and high precision control.

(the command pulse of the open collector positioning module is highest 200kpps.)

Can also meet the needs of high speed, high precision control.

Most suitable analog modules for high speed conversion control.

Can provide a variety of analog and digital analog conversion module products.

These modules have a variety of functions, in the connection of equipment, to achieve the greatest flexibility.

Can meet the inverter control, such as high-speed conversion needs.

A variety of modules with excellent performance,

Meet the needs of various control from analog to location.

Q series module products include a variety of types of I/O, analog and positioning function module.

Can fully meet the switch, sensor, such as the input and output, temperature, weight, flow aand motor, drive control,

As well as the requirements of high-precision control of the positioning of the industry, the control needs of various fields Q38RB.

Can also be used in combination with the CPU module to achieve appropriate control.

The poossibility of expanding control with intelligent function Q38RB.

Providing a variety of analog modules, is the ideal choice for process control applications.

...More relevant models >>>>

Last one: MITSUBISHI Ultra thin main substrate Q35SB

Last one: MITSUBISHI Ultra thin main substrate Q35SB next one: MITSUBISHI Large main substrate Q35BL

next one: MITSUBISHI Large main substrate Q35BL

Related download