Brand sort

MITSUBISHI AJ35PTF-28DS Market price | AJ35PTF-28DS Introduction

Brand:

MITSUBISHI

Country: JAPAN

Name: DC input / silicon controlled output module

Model: AJ35PTF-28DS

Price: 0

MITSUBISHI AJ35PTF-28DS

Series introduction: set a number of basic functions in a small body model.

Screen size: 3.7 inches.

Display color: monochrome.

Mounting type: panel mounting type.

Resolution: 288 * 96.

Display device: STN monochrome.

Host frame color: black.

Power type: DC24V.

Communication interface: with built-in RS-422.

Set a number of basic functions in a compact type.

GT1055/GT1050/GT1045/GT1040:

User storage capacity: 3MB AJ35PTF-28DS

Device USB port.

The standard RS-422/485 and RS-232 interface.

GT1030/GT1020:

User storage capacity: 1.5MB (gt1030) /512kb (gt1020).

Three color LED backlight design, equipment status at a glance.

The standard RS-422/485 or RS-232 interface.

Touch screen, also known as touch screen, touch panel, is a kind of induction type liquid crystal display device can receive contacts and other input signals,

When touching the screen button on the screen,

The tactile feedback system on the screen can drive various connecting devices according to the pre programmed program,

Can be used to replace the mechanical button panel, and by the liquid crystal display screen to create the image of the effect of birth. 2 axes.

2 axis linear interpolation.

Control unit: pulse, mm, inch, degree.

Determine the location of the number of data: 400/1 axis.

40 pin connector.

Control mode: position automatic acceleration and deceleration time: 64-4999ms pulse train output.

Structured text language is a programming language that describes a program with a structured description of the text.

It is a programming language similar to a high level language. In large and medium

Structured text is often used to describe the relationship between the various variables in the control system based on the PLC system.

Mainly used for other programming languages more difficult to achieve the user program.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced.

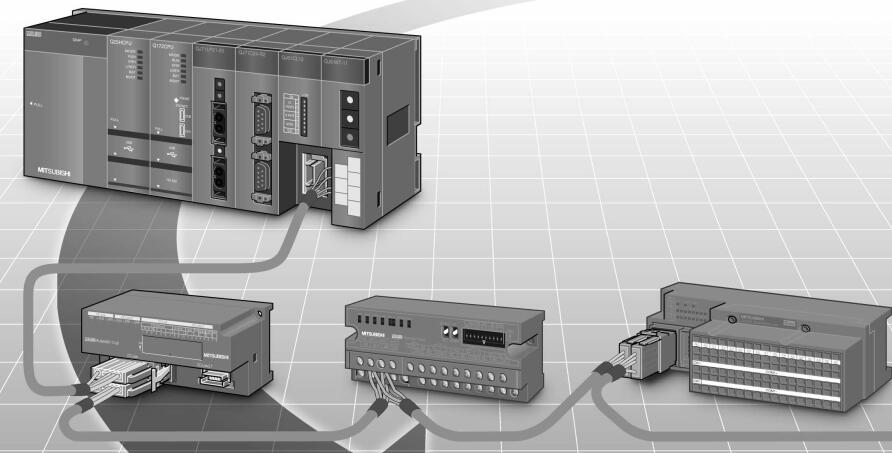

A1SD75 series components show MITSUBISHI in manufacturing and design CNC,

Integrated technical experience in the aspects of frequency converter, servo system and PLC.

These components have a wealth of features that are sufficient to meet the highest requirements in the application of positioning control.

Up to 3 axis linkage operation,

In low cost motion control applications, this component can be used to control the operation of a multi - to 3 axis, which can be used to account for only one slot.

AJ35PTF-28DS Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=AJ35PTF-28DS&select=5

Screen size: 3.7 inches.

Display color: monochrome.

Mounting type: panel mounting type.

Resolution: 288 * 96.

Display device: STN monochrome.

Host frame color: black.

Power type: DC24V.

Communication interface: with built-in RS-422.

Set a number of basic functions in a compact type.

GT1055/GT1050/GT1045/GT1040:

User storage capacity: 3MB AJ35PTF-28DS

Device USB port.

The standard RS-422/485 and RS-232 interface.

GT1030/GT1020:

User storage capacity: 1.5MB (gt1030) /512kb (gt1020).

Three color LED backlight design, equipment status at a glance.

The standard RS-422/485 or RS-232 interface.

Touch screen, also known as touch screen, touch panel, is a kind of induction type liquid crystal display device can receive contacts and other input signals,

When touching the screen button on the screen,

The tactile feedback system on the screen can drive various connecting devices according to the pre programmed program,

Can be used to replace the mechanical button panel, and by the liquid crystal display screen to create the image of the effect of birth. 2 axes.

2 axis linear interpolation.

Control unit: pulse, mm, inch, degree.

Determine the location of the number of data: 400/1 axis.

40 pin connector.

Control mode: position automatic acceleration and deceleration time: 64-4999ms pulse train output.

Structured text language is a programming language that describes a program with a structured description of the text.

It is a programming language similar to a high level language. In large and medium

Structured text is often used to describe the relationship between the various variables in the control system based on the PLC system.

Mainly used for other programming languages more difficult to achieve the user program.

Sequential function flow chart language is designed to satisfy the sequential logic control.

The process of sequential process action is divided into steps and transformation conditions,

According to the transfer condition, the control system is distributed in the function flow sequence,

Step by step according to the sequence of actions.

Each step represents a control function, represented by the box.

In the box, the ladder logic is used to complete the task of the corresponding control function.

This programming language makes the program structure clear and easy to read and maintain,

Greatly reduce the programming workload, shorten the programming and debugging time.

Used in the system of the size of the school, procedures for more complex occasions.

Sequence function flow chart programming language features: to function as the main line, in accordance with the functional flow of the order of distribution, clear, easy to understand the user program,

Avoid the defect of ladder diagram or other languages,

At the same time, the use of ladder language to avoid the use of ladder programming,

Due to the complicated mechanical interlock, the structure of the user program is complex and difficult to understand,

User program scan time is also greatly reduced.

A1SD75 series components show MITSUBISHI in manufacturing and design CNC,

Integrated technical experience in the aspects of frequency converter, servo system and PLC.

These components have a wealth of features that are sufficient to meet the highest requirements in the application of positioning control.

Up to 3 axis linkage operation,

In low cost motion control applications, this component can be used to control the operation of a multi - to 3 axis, which can be used to account for only one slot.

AJ35PTF-28DS Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=AJ35PTF-28DS&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

Melsecnet module

AJ35PTC-CNV-SI

MELSECNET/MINI -S3 data link system, A

MITSUBISHI

Relay output module

AJ35PTF-24R

Output points: 24 points.

Output voltage

MITSUBISHI

DC input / silicon controlled output module

AJ35PTF-56DS

DC input points: 32 points.

Input voltag

Related download

next one:

next one:  Last one:

Last one: