Home

>> Products

>> MITSUBISHI

>> Ans/QnAs series PLC

>> Output module

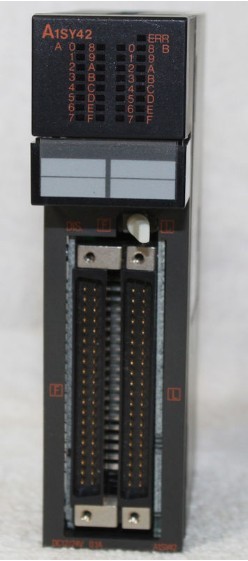

>> A1SY42 | MITSUBISHI Transistor leakage type output module A1SY42

A1SY42 | MITSUBISHI Transistor leakage type output module A1SY42

MITSUBISHI A1SY42 Manual And Instructions

A1SY42 datasheetPDF datasheet

A1SY42 User's Manual

MITSUBISHI A1SY42 Product information and technical parameters:

Brand: MITSUBISHI

Name: Transistor leakage type output module

Model: A1SY42

Output type: transistor drain.

Output points: 64 points.

Load voltage: DC12/24.

Load current: 0.1A.

Connection mode: terminal row.

Common public end points: 32.

Structured text language is a programming language that describes a program with a structured description of the text.

It is a programming language similar to a high level language. In large and medium

Structured text is often used to describe the relationship between the various variables in the control system based on the PLC system.

Mainly used for other programming languages more difficult to achieve the user program.

The structured text programming language uses the computer description method to describe the various kinds of relations between the various variables in the system,

Complete the required function or operation.

Most PLC manufacturers use structured text programming language similar to BASIC language, PASCAL language or C language and other advanced languages,

But in order to be convenient, the expression methods of the statement and the types of statements are simplified.

Structured text programming language features: the use of high-level language programming, you can complete the complex control operations,

Need to have a certain level of computer knowledge and programming skills,

Higher requirements for engineering designers. Poor visibility and operability.

...More relevant models >>>>

A1SY42 datasheetPDF datasheet

A1SY42 User's Manual

MITSUBISHI A1SY42 Product information and technical parameters:

Brand: MITSUBISHI

Name: Transistor leakage type output module

Model: A1SY42

Output type: transistor drain.

Output points: 64 points.

Load voltage: DC12/24.

Load current: 0.1A.

Connection mode: terminal row.

Common public end points: 32.

Structured text language is a programming language that describes a program with a structured description of the text.

It is a programming language similar to a high level language. In large and medium

Structured text is often used to describe the relationship between the various variables in the control system based on the PLC system.

Mainly used for other programming languages more difficult to achieve the user program.

The structured text programming language uses the computer description method to describe the various kinds of relations between the various variables in the system,

Complete the required function or operation.

Most PLC manufacturers use structured text programming language similar to BASIC language, PASCAL language or C language and other advanced languages,

But in order to be convenient, the expression methods of the statement and the types of statements are simplified.

Structured text programming language features: the use of high-level language programming, you can complete the complex control operations,

Need to have a certain level of computer knowledge and programming skills,

Higher requirements for engineering designers. Poor visibility and operability.

The use of A1STA32 can significantly reduce the wiring time I/O 32 type of connector assembly,

Neither welding, without thread stripping,

It only needs to cut a wire and insert the wire into the terminal hole of the A1STA32,

A1STA32 in the blade will cut wire insulation surface,

To make contact and hold a good conductor MITSUBISHI A1SY42. I/O slots: 8 slots.

Can you install the power module.

Outline dimension: 365*130 A1SY42

There are two types of extended floor,

A power module can be inserted, and the other one is not.

The choice of any type of substrate depends on the total DC5V current consumption and the power supply on the CPU main substrate.

If the total demand is less than the power output, no additional power supply,

Then you can choose a more economical expansion board MITSUBISHI A1SY42.

Both ends of the main base plate of the CPU have an expansion interface, and can be used for extending the cable connection. Type of input: DC source.

Input points: 16 points.

Input voltage: 12/24DC.

Input current: 3/7mA.

Connection mode: terminal row.

Common common point: 32.

Functional block diagram language is a kind of PLC programming language, which is similar to digital logic circuit MITSUBISHI A1SY42.

The function module is used to represent the function of the module,

Different function modules have different functions.

Functional module figure programming language features: functional block diagram programming language is characterized by a functional module for the unit,

Analysis and understanding of the control scheme is simple and easy: function module is to use graphical form of expression,

Intuitive, for a digital logic circuit based on the design of the staff is very easy to master the programming;

Control system with complex scale and complex control logic,

Because the function module diagram can clearly express the function relation, the programming debugging time is greatly reduced. 10Mbps transmission speed, the computer as the support of the flexible manufacturing system at the plant level, the requirements of more and more data flow,

High transmission speed can be guaranteed to increase the amount of transmitted data while maintaining the minimum time to transfer and receive data between programmable controllers.

The response time of PLC is the interval between the time of the change of the external output signal of the PLC and the time of the change of the external output signal which is controlled by it,

Lag time, this is the time constant of the input circuit,

The time constant of the output circuit, the arrangement of the user statement and the use of the instruction,

The cycle scan mode of PLC and the way of PLC to refresh the I/O and so on.

This phenomenon is called the I/O delay time effect.

Switch volume control is designed to,

According to the current inpuut combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order A1SY42.

So, sometimes also known as the order control.

And seqquential control is divided into manual, semi-automatic or automatic A1SY42.

And the control principle is decentralized, centralized and hybrid control three.

Neither welding, without thread stripping,

It only needs to cut a wire and insert the wire into the terminal hole of the A1STA32,

A1STA32 in the blade will cut wire insulation surface,

To make contact and hold a good conductor MITSUBISHI A1SY42. I/O slots: 8 slots.

Can you install the power module.

Outline dimension: 365*130 A1SY42

There are two types of extended floor,

A power module can be inserted, and the other one is not.

The choice of any type of substrate depends on the total DC5V current consumption and the power supply on the CPU main substrate.

If the total demand is less than the power output, no additional power supply,

Then you can choose a more economical expansion board MITSUBISHI A1SY42.

Both ends of the main base plate of the CPU have an expansion interface, and can be used for extending the cable connection. Type of input: DC source.

Input points: 16 points.

Input voltage: 12/24DC.

Input current: 3/7mA.

Connection mode: terminal row.

Common common point: 32.

Functional block diagram language is a kind of PLC programming language, which is similar to digital logic circuit MITSUBISHI A1SY42.

The function module is used to represent the function of the module,

Different function modules have different functions.

Functional module figure programming language features: functional block diagram programming language is characterized by a functional module for the unit,

Analysis and understanding of the control scheme is simple and easy: function module is to use graphical form of expression,

Intuitive, for a digital logic circuit based on the design of the staff is very easy to master the programming;

Control system with complex scale and complex control logic,

Because the function module diagram can clearly express the function relation, the programming debugging time is greatly reduced. 10Mbps transmission speed, the computer as the support of the flexible manufacturing system at the plant level, the requirements of more and more data flow,

High transmission speed can be guaranteed to increase the amount of transmitted data while maintaining the minimum time to transfer and receive data between programmable controllers.

The response time of PLC is the interval between the time of the change of the external output signal of the PLC and the time of the change of the external output signal which is controlled by it,

Lag time, this is the time constant of the input circuit,

The time constant of the output circuit, the arrangement of the user statement and the use of the instruction,

The cycle scan mode of PLC and the way of PLC to refresh the I/O and so on.

This phenomenon is called the I/O delay time effect.

Switch volume control is designed to,

According to the current inpuut combination of the switch quantity and the history of the input sequence,

So that PLC generates the corresponding switching output,

In order to make the system work in a certain order A1SY42.

So, sometimes also known as the order control.

And seqquential control is divided into manual, semi-automatic or automatic A1SY42.

And the control principle is decentralized, centralized and hybrid control three.

...More relevant models >>>>

Last one: MITSUBISHI Transistor leakage type output module A1SY41

Last one: MITSUBISHI Transistor leakage type output module A1SY41 next one: MITSUBISHI Transistor leakage type output module A1SY50

next one: MITSUBISHI Transistor leakage type output module A1SY50

Related download