Brand sort

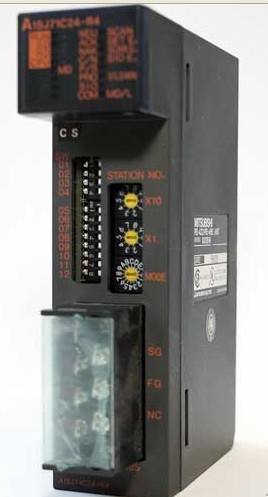

MITSUBISHI A1SJ71C24-R4 Market price | A1SJ71C24-R4 Introduction

Brand:

MITSUBISHI

Country: JAPAN

Name: Computer link module

Model: A1SJ71C24-R4

Market price: U.S.$ 813.56

(The following are the market open price not sales price!)

(The following are the market open price not sales price!)

MITSUBISHI A1SJ71C24-R4

Capacity: 16M bytes.

Better user experience data recording function.

Easy to record, no need to program.

Simply through the special configuration tool wizard to easily complete the settings,

The collected data can be saved in CSV format to SD storage card.

Can be effectively used to save the CSV file to facilitate the creation of a variety of reference materials,

Including daily reports, generate reports and general reports A1SJ71C24-R4

These data can be applied to the data analysis, tracing, etc..

Simply insert the SD memory card, you can automatically record.

Simply insert the SD in the CPU to save the record setting file, you can automatically start recording.

Even when remote data collection is required,

After receiving a record setting file by mail and copy it to the SD memory card,

Can immediately start recording."MITSUBISHI general purpose AC servo amplifier MELSERVO-J2-Super series.

Rated output: 1.0kw.

Built in positioning function.

Voltage: 3 phase AC200VAC or single phase AC230V.

Compatible with "MR-J2S- CP-S084" - servo amplifier and interface unit "MR-J2S-TO1" positioning by CC-Link

Simply setting the point table.

AC servo can be used as the driving source of the field network.

Using servo amplifier built-in positioning function, position data and speed data, you can set the CC-Link.

Start, stop and display can also be transmitted through the CC-Link.

Serial communication reduces wiring.

AC servo distributed control system can be easily constructed. "The length of the line: 2M.

IP level: IP65.

Direct type.

Bending life: high bending life.

The cable is not shielded.

Electric motor power supply cable for HF-KP/HF-MP series (motor shaft with side extraction). DC input points: 32 points.

Input voltage and current: 3/7mA, DC12/24V.

Response time: 10ms.

Positive pole sharing.

Output points: 16 points.

Output voltage and current: 100mA/1, DC12/24V point.

Response time: 2ms.

48 point /1 public side (input and output sharing).

Output form: transistor output, leakage type.

40 pin connector.

Number of stations: 1 stops.

Type remote I/O unit (twisted pair data connection).

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system.

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

A1SJ71C24-R4 Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=A1SJ71C24-R4&select=5

Better user experience data recording function.

Easy to record, no need to program.

Simply through the special configuration tool wizard to easily complete the settings,

The collected data can be saved in CSV format to SD storage card.

Can be effectively used to save the CSV file to facilitate the creation of a variety of reference materials,

Including daily reports, generate reports and general reports A1SJ71C24-R4

These data can be applied to the data analysis, tracing, etc..

Simply insert the SD memory card, you can automatically record.

Simply insert the SD in the CPU to save the record setting file, you can automatically start recording.

Even when remote data collection is required,

After receiving a record setting file by mail and copy it to the SD memory card,

Can immediately start recording."MITSUBISHI general purpose AC servo amplifier MELSERVO-J2-Super series.

Rated output: 1.0kw.

Built in positioning function.

Voltage: 3 phase AC200VAC or single phase AC230V.

Compatible with "MR-J2S- CP-S084" - servo amplifier and interface unit "MR-J2S-TO1" positioning by CC-Link

Simply setting the point table.

AC servo can be used as the driving source of the field network.

Using servo amplifier built-in positioning function, position data and speed data, you can set the CC-Link.

Start, stop and display can also be transmitted through the CC-Link.

Serial communication reduces wiring.

AC servo distributed control system can be easily constructed. "The length of the line: 2M.

IP level: IP65.

Direct type.

Bending life: high bending life.

The cable is not shielded.

Electric motor power supply cable for HF-KP/HF-MP series (motor shaft with side extraction). DC input points: 32 points.

Input voltage and current: 3/7mA, DC12/24V.

Response time: 10ms.

Positive pole sharing.

Output points: 16 points.

Output voltage and current: 100mA/1, DC12/24V point.

Response time: 2ms.

48 point /1 public side (input and output sharing).

Output form: transistor output, leakage type.

40 pin connector.

Number of stations: 1 stops.

Type remote I/O unit (twisted pair data connection).

According to the control requirements of the system, using the appropriate design method to design MITSUBISHI PLC program.

Procedures to meet the requirements of system control as the main line,

Write one by one to achieve the control function or the sub task of the program,

Gradually improve the functions specified by the system.

MITSUBISHI PLC detection, fault diagnosis and display and other procedures.

These procedures are relatively independent, generally in the basic completion of the program design and then add.

Hardware simulation method is to use a number of hardware equipment to simulate the generation of the signal,

The signals are connected to the input end of the PLC system in a hard wired way, and the timeliness is strong.

Software simulation method is in the MITSUBISHI PLC in the preparation of a set of simulation program,

The simulation provides the field signal, which is simple and easy to operate, but it is not easy to guarantee the timeliness.

Simulation of the process of debugging, debugging method can be used to segment, and the monitoring function of programmer.

A1SJ71C24-R4 Operation manual / Instructions / Catalog download link: /searchDownload.html?Search=A1SJ71C24-R4&select=5

...more relevant model market price >>>>

Related products

MITSUBISHI

MODBUS interface module

A1SJ71UC24-R4-S2

Data format: RTU.

Data its: 8.

A1SJ71UC

MITSUBISHI

Network module

A1SJ71QE71N-T

10BASE-T.

MITSUBISHI

Ethernet module

A1SJ71E71N-B2

10BASE2.

PLC is introduced y the relay

MITSUBISHI

Modular

A1SJ71B62-S3

Signal transmission device B/NET interfa

Related download

next one:

next one:  Last one:

Last one: